The Aggregate impact value indicates a relative measure of resistance of aggregate to impact load which has different effect than the resistance to gradually increasing compressive stress. A test designed to evaluate the toughness of stones or the resistance of the aggregates to fracture under repeated impacts is called impact test. The aggregate impact value gives a relative measure of the resistance of an aggregate to sudden shock or impact.

Page Contents

Apparatus Required

- Impact Value testing machine

- Electrical oven

- Tamping rod

- Weigh balance

- IS Sieves -(12.5mm,10mm &2.36mm)

The procedure of the test

- Aggregate sample shall consists of particles passing on 12.5mm Sieve and retained on 10mm sieve.

- The aggregate to be tested shall be dried in an oven for a period of 4 hours at a temperature of 100 to 110° C.

- The test samples shall be filled in three layers and tamped with 25 strokes per layer in the measuring container.

- The surplus test sample shall be filled in three layers &b net weight of the test sample to fill the measuring container shall be weigh.

- The cup shall be fixed firmly and the whole of the test sample placed in it and compacted by a single tamping of 25 strokes of the tamping rod.

- The test sample shall be subjected to a total of 15 blows each at an interval of not less then one second of the aggregate impact machine.

- The crushed test sample shall then be removed from the cup and the whole of it sieved on the 2.36mm test sieve until no further significant amount passes in one minute.

- The test sample retained and passing on 2.36mm test sieve shall then be weighed.

- Calculate the weight of test sample passing 2.36mm sieve with the weight of whole test sample filled in the cup and report test results.

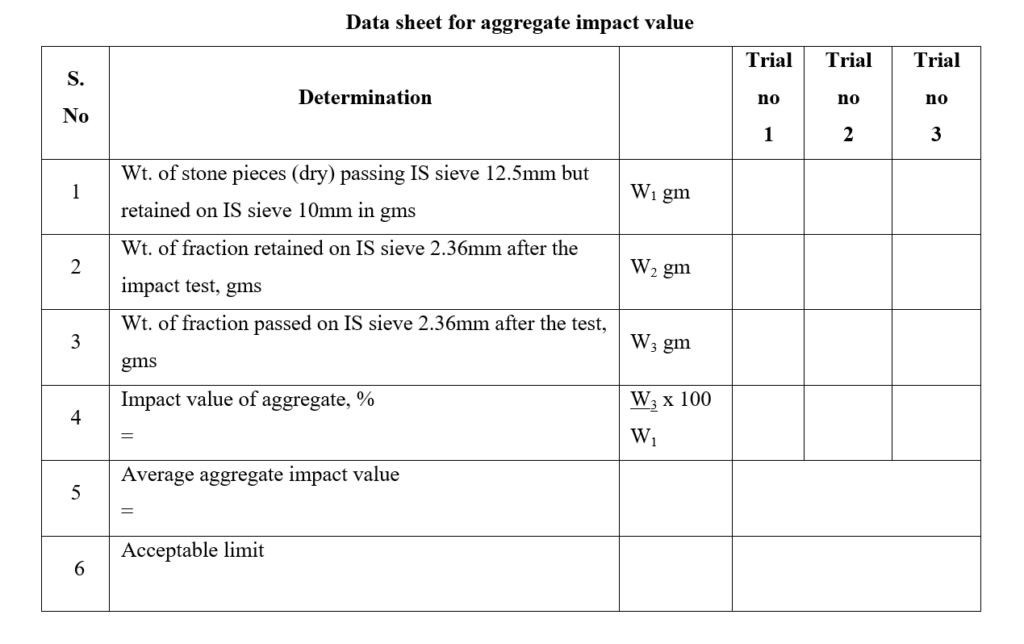

Datasheet for aggregate impact value

RELATED POSTS

View all