Page Contents

Apparatus Required

- High-frequency mortar cube vibrator

- cube moulds (70.6mm×70.6mm×70.6mm) size

- Gauging trowel

- graduated glass cylinder

- poking rod

- standard sand conforming to IS 650-1967 & CTM

The procedure of the test

- On a non-porous surface, place a mixture of 200gms of cement and 600gms of standard sand.

- Mix the cement and the standard sand in 1 :3 proportion by weight, for at least 1 minute in a dry state, add specified quantity of water (P/4+3.0)% by total weight of cement and sand to the mixture of cement and sand. mix thoroughly for 3 to 4 minutes with the help of a trowel.

- Oil the mould and fix it on the vibrating machine and clamp properly, fill the mortar in the mould and the mortar shall be prodded 20 times in about 8 seconds to ensure elimination of entrained air, compact the mortar by vibrating the cubes in the vibrating machine(With vibrator speed of 12000 + or -400 Vib/min) for 2 minutes.

- Keep the filled moulds at a temperature of 27° C +/- 2°C in an atmosphere of at least 90% relative humidity for 24 hrs.

- Demould after 24 hrs and submerge the cubes in clean fresh water for curing, till they are tested ( Renew the water every 7 days).

- Test the cubes for crushing in CTM immediately after the ages of 3,7 & 28 Days (min -3cubes for each age ) period is calculated from the time of addition of water to the dry cement & sand.

- Load on specimen shall be applied steadily and uniformly starting from zero @ 35 N/ Sq.mm/min till cube failure mode, note the load at failure of 3 cubes, average of 3 cubes is to be tested for compressive strength.

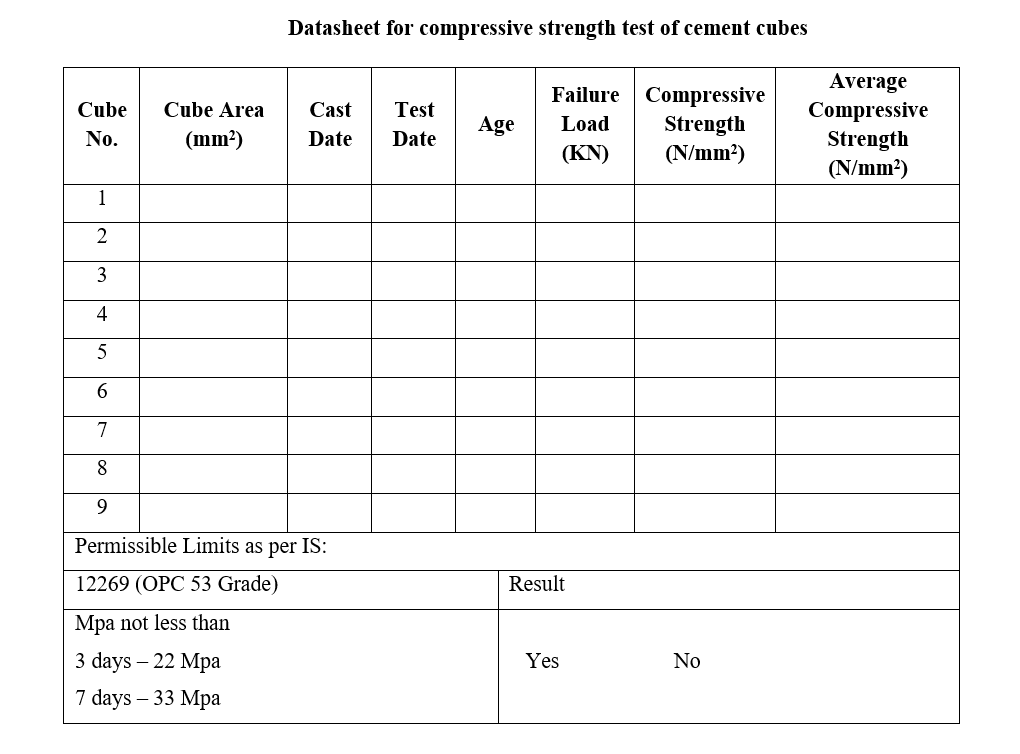

Datasheet for compressive strength test of cement cubes

RELATED POSTS

View all